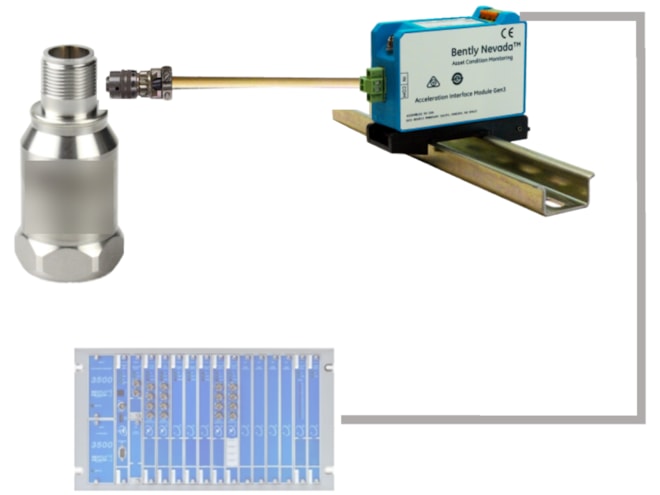

Bently Nevada 350620 Low Frequency Velocity Transducer System

Detects the vibration of the stator core, stator frame, and bearing housing supports. Designed to provide early warning of pending machinery problems to help diagnose problems.

Overview

Features

- Sensitivity: 500 or 1,000 mV/in/s (±8%) depending on model

- Frequency response:

- 185M3314: 0.5 to 2,500 Hz

- 185M3313: 0.7 to 2,500 Hz

- Dynamic range:

- 185M3314: ≤10 in/s

- 185M3313: ≤5 in/s

- Electrical noise: 3 mVRMS typical

- Output impedance: 50 ±3 Ω

- DC bias voltage output: +10.0 ±0.15 VDC

Description

The Bently Nevada 350620 Low Frequency Velocity Transducer System (LFVTS) detects low-frequency and low-amplitude vibrations in slow-speed rotating machines, such as hydroelectric turbines. This system plays a critical role in monitoring machinery components like stator cores, stator frames, and bearing housings. Areas where early detection of vibration anomalies can help prevent significant operational damage. The LFVTS provides both shaft-relative and bearing-absolute vibration data, making it an essential diagnostic tool for predictive maintenance.

Documents

Need Help? Call a Vibration (Cal) engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET